Best Selling Milk Line Kombucha Producing Machine 1000L Small Beer Production Line Micro Brewing Brewery Equipment

Overview Product Description 1000 Liter Craft Beer Brewhouse Brewery Beer Equipment Plant > Brewhouse Combination Divers

Description

Basic Info.

| Model NO. | MT-1000L |

| Power Source | Electric Steam,Gas,Direct Fire |

| Automatic Grade | Semi-Automatic |

| Welding | Arc Argon Protection |

| Weight | Depending on Capacity |

| After Sales Service | Installation and Equipment Commission |

| Capacity | 1000L Beer Equipment Plant |

| Brewhouse Heating | Steam Jacket , Electric Tube, Direct Fire |

| Control Unit | Temp. Controller, HMI, PLC or Touching Screen |

| Dimension(L*W*H) | Depending on Capacity |

| Thickness | Inner:3-4mm, Exteior:2mm |

| Material | SUS304 Stainless Steel |

| Cooling Unit | Chiller with Glycol Tank |

| Transport Package | Plastic Film, Plywood Case; Container; |

| Specification | Customized |

| Trademark | METO |

| Origin | Jinan, China |

| HS Code | 84384000 |

| Production Capacity | 10 Set/Sets Per Month Stainless Steel Brewhouse |

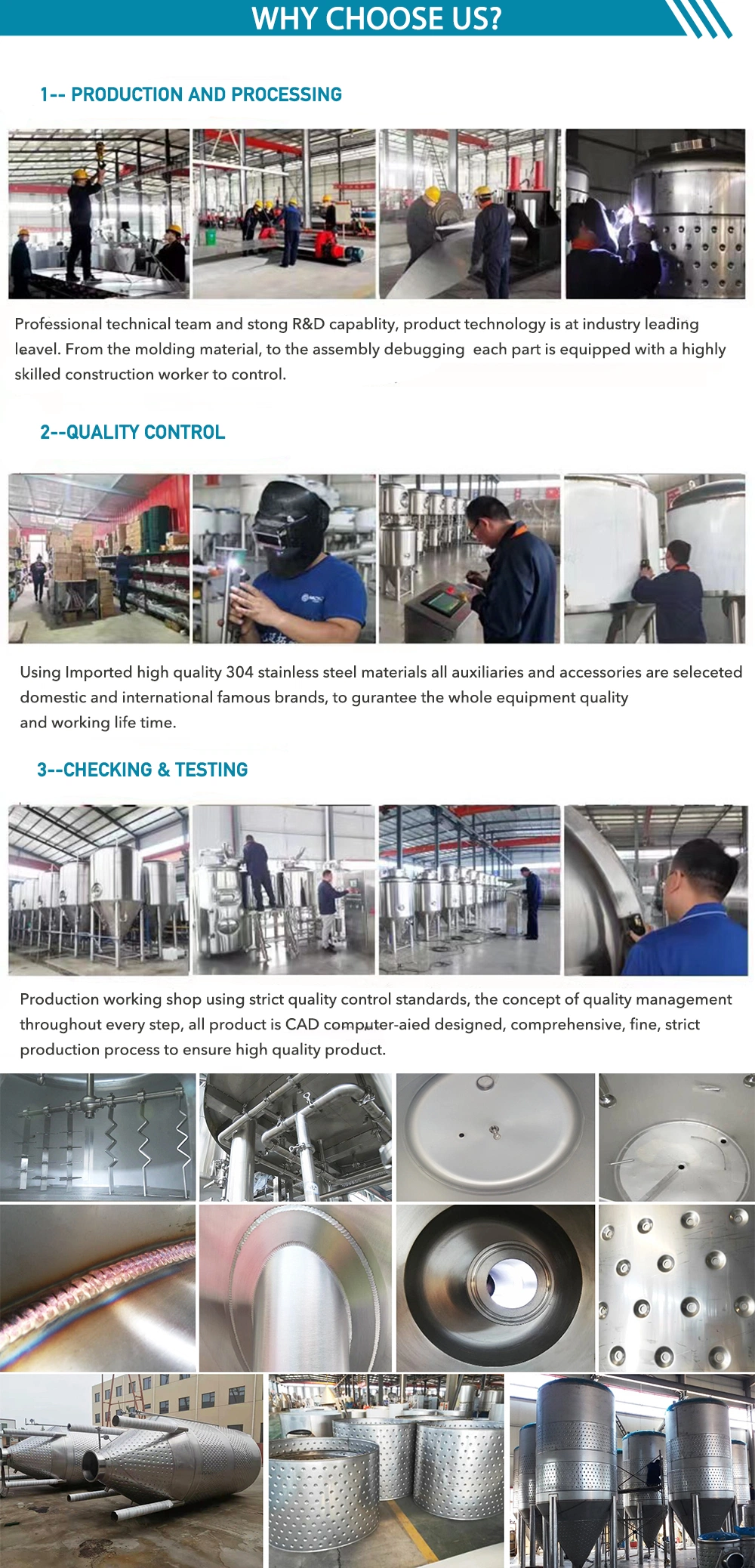

Product Description

> Decoction,infusion,multi-step infusion mashing can be realized.

> Electric,Steam,Gas directly fire heating source for optional

> 15-20 days free installation and training service offered by profession engineer.

> Mirror polishing and wire drawing SUS 304 for optional,thickness:3-4mm

> Rational layout, Humanized design and convenient operation

Brewhouse system: SUS 304, Inner 3mm; External 2mm; Platform with handrails Inner surface treatment: welds grinded to Ra 0.4µm.CIP cleaning ball

Insulation: Polyurethane-thickness 80 mm.

Equip with : Agitator, Rake knife, sieve plate ects

Fermenting system consist by many fermentation tanks. All tanks are made by SUS304 Stainless Steel, which meet domestic and international food safety and hygiene standards.

They are cylindrical cone bottom tank, the cone is 54-72 degree. Their internals have a protective film by pickling passivation, and equipped with 80mm polyurethane insulation. The tanks with dimple plate on cone and side, they are cooled by glycol, water and alcohol water.

Configuration List of 1000L Brewing Equipment

| UNit | Components | Capacity | Specification |

| Milling | Miller | 500KG/H | Double Roller,Noise<60db |

| Brewhouse | Mash/Lauter tun | 1000L | Mashing Process:Decoction.Infusion.Multi-step infusion |

| Brew Kettle/Whirlpool Tank | 1000L | Heating source:Steam,Electric,direct fire SUS304/Red copper | |

| Hot Water Tank | 1500L | Heating source:Steam,Electric,Gas | |

| Heat exchanger | 5 SQM | Stainless steel plate | |

| Fermentation tank | Fermentation Tank (The number according to customer requirements) | 1000L or 2000L | Top manway/Side manway Drying hop port to brew IPA Dimple Plate Cooling jacket Carbonation port to fill CO2 |

| Yeast Adding Tank | 10-20 L | SUS304 Stainless Steel | |

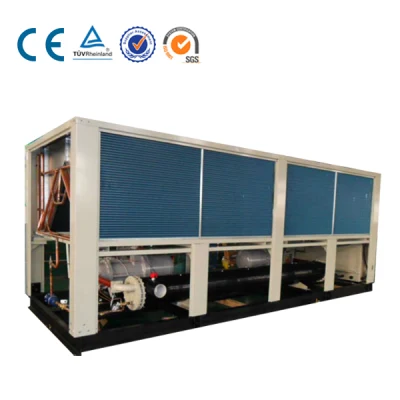

| Cooling System | Glycol Water tank | 2000L | Equiped with PU level indicator |

| Chiller | 8Hp | UL/CE certified electric elements,Copeland compressor | |

| Pump | 3T/H | ||

| Cleaning System | Disinfection Tank | 100L | SUS304 full welded |

| Alkali Tank | 100L | ||

| Pump | 3T/H | ||

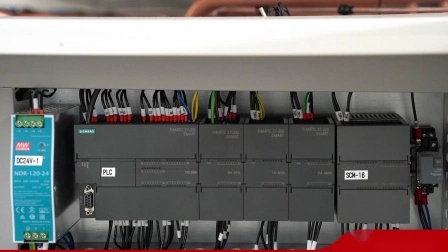

| Control System | Control Cabinet | PID or PLC | |

| Optional | Auger System Grain CaseGrist Hydrator Piping flow panel for BrewhouseBrewhouse Separate PLC ControllerSteam Boiler Customized ...... | ||

PS: All the specifications can be customized according to your requests.

Packaging Details

1.LCL/FCL(20GP/40GP/40HQ).2.Packed with plastic film in fumigation free wooden case or fixed with iron frame.3.Up to export standard, suitable for delivery.4.Customer's requirements available.

FAQOur service for you:

1. Free consultation service before, during, and after sales Layout plan in 3D or CAD drawings of your brewery;2. Professional engineers going abroad for the installation ,debugging, and training, all the travelling cost and locate food, and hotel shall be afforded by the buyer3. The installation period is about 15 days including assembling brewing tanks and training the operator. It is free of charge within 15 days. The buyer will be charged USD 50 per day for each engineer for the extended installation.4. Round the clock assistance via phone, e-mail, Skype, Whatsapp, MSN, or any other communication method available to the customer.5. Assisting purchased Facilities by seller including bottling system, steam boiler, water treatment,etc. should be installed separately. If needed, cost calculate additionally. 6. Brewing technology, brewing formula, can be offered available7. More spare parts are available to offered freely.

Our Contact

Send now