Factory Directly Sell Glycol Brewery Water Chiller Drinking Cooling System Laser with Wholesale Price

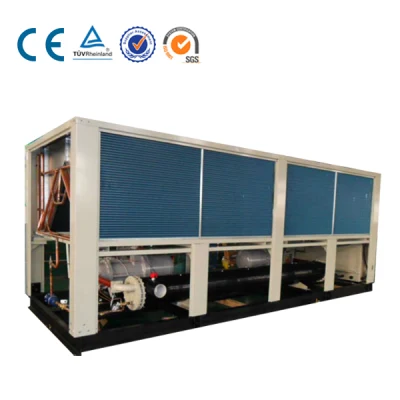

Product Description Screw Type Water Cooled Chiller Cooling 130-420kW Application areas Industry process, precision,trad

Description

Basic Info.

| Model NO. | AW8-100 |

| Application Fields | Industry |

| Application Machine | Industry |

| Certification | CE |

| Condition | New |

| BMS System | Optional |

| Heat Exchanger | Shell and Tube Type |

| Refrigerant Valves | Emerson/Danfoss |

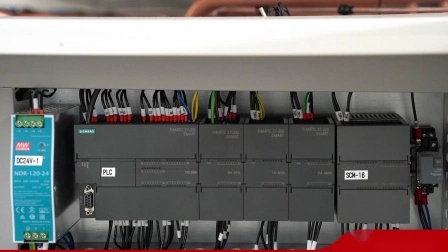

| Control | Siemens/Punp |

| Heat Recovery | Optional |

| Compressor Type | Screw Type |

| Electric Parts | Schneider |

| Compressor Brand | Hanbell/Fusheng/Bitzer |

| Refrigerant | R22/R407c/R134A |

| Power Supply | 380~415V/3pH/50Hz/60Hz |

| Transport Package | Tandard Package Fit for Seaworthy Transport |

| Specification | 130kw-4500kw |

| Trademark | Amrta or OEM |

| Origin | China |

| HS Code | 8418612090 |

| Production Capacity | 3000PCS/Year |

Product Description

Product Description

Screw Type Water Cooled Chiller

Cooling 130-420kW

Application areas

Industry process, precision,traditional manufacturing, food processing, government project, pharmacetical.

Characteristics

29 sizes available ranging from 130 kW to 2500 kW cooling capacity.

Acting as multi-function unit such as cooling, heating, sanitary hot water separately or simultaneously.

Wide application as hotel, apartment, villa, factory, shopping center, office building, school, etc.

Semi- hermetic screw compressor for the whole range. Each compressor is equipped with a crankcase heater and a built-in electronic

protection with temperature sensor located directly in the motor winding and on the discharge line.

The refrigerant circuit is complete with sight glass, filter drier, high and low pressure gauges, solenoid valve, electronic expansion valve, high and low pressure switch.

Shell and tube dry expansion type condenser, factory insulated with flexible close cell material.

Shell and tube evaporator, higher efficiency less water consumption, easy maintenance and cleaning, factory insulated with flexible close cell material.

The electric panel consists of compressor breaker, compressor contactor, phase sequence relay, control circuit breaker, microprocessor control with function display.

LCD display, touch screen control panel as standard.

Automatic operation dramatically reducing maintenance cost thanks to reliable microprocessor system.

An infinitely variable capacity control system that is capable of exactly matching the demand requirement of the system is to be supplied. This system is to provide precise and stable control of supply water temperature over the complete range of operating conditions.

Optional

Desuperheater as optional.

Electronic controller with BMS system.

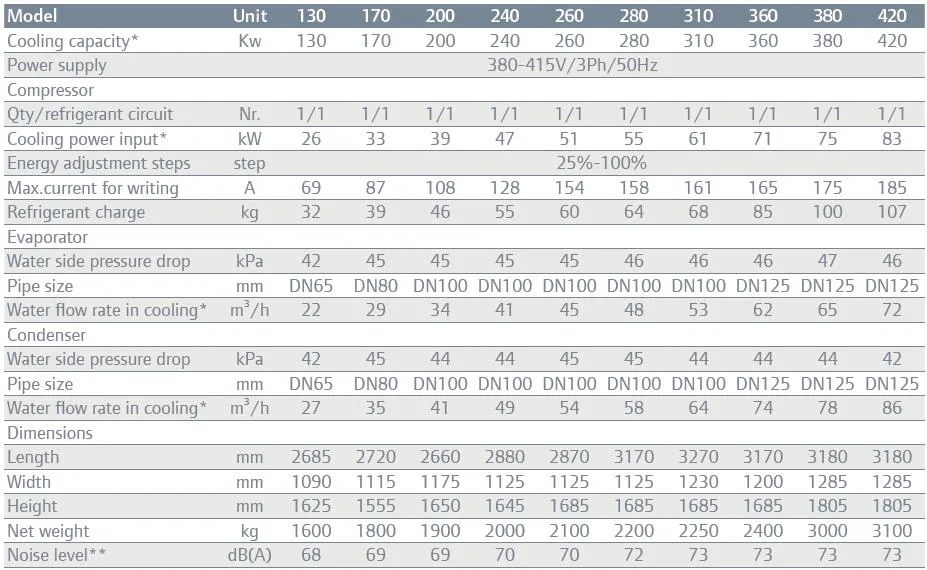

Technical Data

* Performance values refer to the following conditions:

Condenser water inlet/outlet temperature: 30ºC/35ºC, evaporator water inlet/outlet temperature: 12ºC/7ºC.

** Noise level measured in free field condition at distance of 1 meter.

Prev: Industrial Low Temperature Glycol Chiller Cooling System

Next: 35% Ethylene Glycol Dry Cooling System for Chemical Industry

Our Contact

Send now