3 Vessels Stainless Steel 1000L Micro Craft Beer Brewing Equipment From Cassman

Description

Basic Info.

| Model NO. | CM-1000 |

| Processing Material | Stainless Steel SUS 304/Red Copper |

| Process | Weld, Polish and Test |

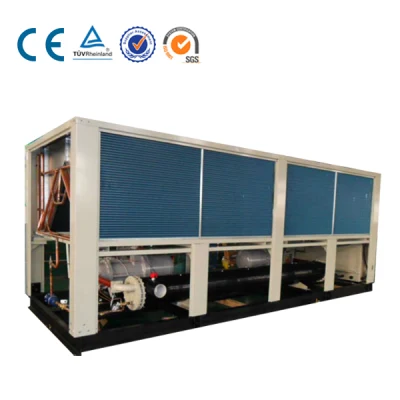

| Cooling Way | Glycol Dimple Cooling Jacket |

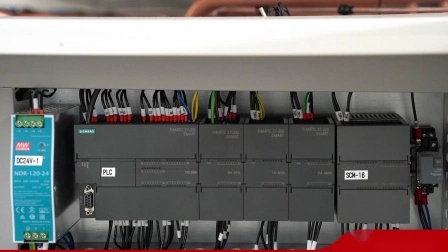

| Control System | PLC/ Pid |

| Size | Customized |

| Fermenter | Customized |

| Pressure | Test 3 Bar, Work 0.5 Bar |

| Test | Before Shipping |

| Logo | Customized |

| Insulation | Rock Wool/Polyurethane |

| Pipes | Include |

| Motor | Include |

| Capacity | 50L-5000L |

| Work Platform | Include |

| Heating Way | Gas/ Electric/Steam |

| Hot Water Tank | Include |

| Thickness | Inner 4mm/External 2mm |

| Transport Package | Wooden Package or Iron Frame |

| Specification | 1000L |

| Trademark | Cassman |

| Origin | Jinan China |

| HS Code | 8438400000 |

| Production Capacity | 500 Sets/Year |

Product Description

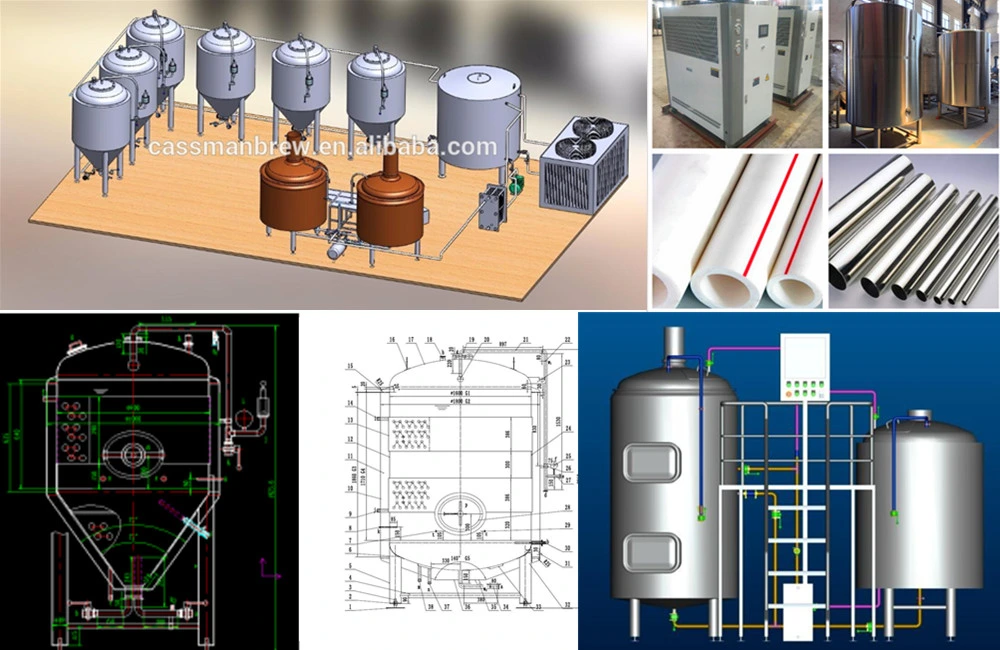

3 Vessels Stainless Steel 1000L Micro Craft Beer Brewing Equipment From Cassman1. 1000L Mash tun.2. 1000L Lauter tank, VFD top motor, Reversible motor for spent malt. False bottom.3. 1000L Kettle/Whirlpool. steam heating, whirlpool inlet. 4. 2000L hot water tanks with hot liquid tank and level gauge. 5. TC connections Brewing pipelines, wort grant, hops filter, heat exchanger, Aeration system, pump, sparging, CIP, work platform etc.6. Control panel for wort pump, motor, Steam valve, temperature sensor of each tankThe configuration and details can be customized.

1000L/H Plate heat Exchanger Wort cooling, Two stages• Effective cooling area: 10 M² (1000L/H)• Wort temperature 96°in, and 8°out.• Two inlet/outlets for glycol water and cold water• Stainless steel 304 Corrugated plates• Full detachable for regular thorough cleaning• Thermometer for wort outlet temperature controlling

Wort aeration• Combined oxygenator and temperature gauge• With sight glass• Sanitary wort aeration mounted with carbonation stone• The amount of oxygen is adjustable• Range of temperature measuring: 0-100°CHop filter or hop tank• Direct filter• Tri Clamp connections.• Connected with the heat exchanger before cooling

Details of 3 Vessels Stainless Steel 1000L Micro Craft Beer Brewing Equipment From Cassman

• Working capacity:1000L(+25% Head space)• Tank size can be customized• Interior Shell:SUS304 Stainless Steel,thickness: 3.0mm;• Exterior Shell:SUS304 Stainless Steel,thickness: 2.0mm;• 100% TIG welding with pure argon gas shield• Interior Finish: Pickling passivation• Insulation:Polyurethane-thickness:80mm.• Heating: steam jacket, electric or directly fire• Lauter tank Grain rake with motor and turbine reducer, Power: 0.75KW,• The motor with Frequency converter• LED sight light• Full size glass top mounted man way• Lauter tank equip with Side mounted grain outdoor with grain chute, Laser cutting V-wire • False Bottom/Sieve plate,with handle, Plate thickness:0.7 mm, form:Strip-shaped holes, Easy clean and detachable sparging spray ring• 360°coverage CIP spraying ball with 2 pieces• PT100 temperature sensor• Adjustable support legs 4 pieces.

| Grist Hydrator | Led Light | Agitotor | Thermometer |

| Electric heating tube | PT100 | Rake Knife | VFD Motor |

| Plate heat Exchanger | Bottom agitator Motor | CIP cleaning ball | Heating device |

Package and shipping

3 Vessels Stainless Steel 1000L Micro Craft Beer Brewing Equipment From Cassman will be well packaged to avoid clash during the sea or air transportation in case of causing damage to the surface of our products.LCL: Standard wooden caseFCL: Packaged with Iron frame and be bound firmly.All equipment ship from Tsingdao Port

Jinan Cassman Machinery Co., Ltd

Established in 2016, Jinan Cassman Machinery Co., Ltd. is located in the High-tech Zone, Jinan City, Shandong Province, we mainly engaged in beer equipment, whiskey distillery equipment, biological fermentation and environmental protection equipment, etc. Jinan Cassman is a production-oriented enterprise with R & D, Manufacture, Sales and Service capabilities. There are more than 40 production employees, more than 10 middle and senior technical personnel, and 8 after-sales service personnel. With the German TUV Rheinland certification, Cassman can design and produce pressure vessels in accordance with the EU CE-PED standard.

The factory covers an area of nearly 8,000 square meters and it has three processing workshops: container processing, welding and cutting, and assembly and commissioning. It is equipped with laser cutting machines, CNC machines, argon arc welding machines, automatic polishing machines, stainless steel uncoiling & bending machines, pressure vessel detectors and other advanced stainless steel processing and assembly tools.

Jinan Cassman is mainly specialized in micro and medium-sized brewery equipment(50L-5T), whiskey and gin equipment, sewage treatment evaporator and other stainless steel equipment. Its products have been widely exported to more than 50 countries and regions such as the European Union, the United States, Russia, Canada, Japan, South Korea, Australia, Southeast Asia, etc. With long-term cooperative and exchange relations with the Japanese Brewers' Association, the American Brewers' Association, the British Buxton Craft Brewery, the American Anchor Craft Brewery, and the leading Chinese whisky companies, Jinan Cassman has won the unanimous affirmation of users from all over the world!

Based on the philosophy of "leading technology, excellent quality, and perfect service", Jinan Cassman will continue to catch up with the world's advanced design level, build the core technology of China's intelligent manufacturing, and seek common development with customers, employees, and suppliers!

Our Service

Before-Sales Service

1. Layout Design for new build breweryOur experienced engineer( more than ten years) will provide the detailed layout according to your brewery, if needed, we will fly to your brewery at our cost. 2. Exist Brewery ExpansionExpansion of the brew house, beer tanks, or other parts, we will design and manufacture as per your exist brewery. 3. Effective business communication Our sales team are young and rich of experience, we are full of passion, all of us have been in this business line for more than 8 years, and they are graduated from UK, Russia etc. 4. Brewing consultantCassman also bult a good relation with Shandong university and other institutes who are expert in beer brewing, we are capable toprovide the most advanced brewing technology.

After-Sales Service

1. Guarantee: 2 years2. Installation: Our engineers team will provide you the perfect installtion and commissioning service. Almost of them have been to 5 countries even more. 3. Our appointed agents are in US, Europe, Russia and other ten countries, they will provide you 24 hours service.

Commercial terms

1- Payment terms: 40% deposit, 60% before delivery.2- Manufacture time: 40 days after deposit.3- Warranty: 2 years for the tanks, 6 months for the electrical parts.4- Layout design: Cassman will provide vessels drawing, brewery layout, brewing flow chart, piping diagram.5- Installation: Cassman will send 1-2 engineers for the installation, salary is USD 80/day, the buyer will take charge of the air ticket, visa and hotel for the engineer.

Cases

1000L brewery system in Russia

1000L brewery system in the UK

10BBL brewery system in the US1000L brewery system in Australia

Thanks and CheersJinan Cassman Machinery Co., Ltd

Our Contact