D50: 10

Description

Basic Info.

| Model NO. | CUM-F |

| Object | Mineral Material |

| Crushing Degree | Ultra-Fine Mill |

| Crushing Style | Grinding and Impact |

| Principle | Cylinder Culling |

| Cutter Material | Hard Alloy |

| Parameter / Model | Cum 160f-360f |

| Sieve Hole Size | 0.2mm-3mm |

| Output (Kg/H) | 5-500 |

| Grinding Fineness(Mesh) | 20-325 |

| Power (Kw) | 3-15 |

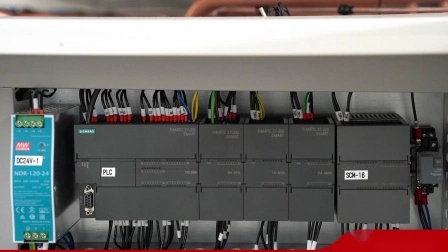

| Control | PLC Programming Control |

| Grinding Disc | 150-730mm |

| Max Rotation Speed | 2800-12000 R/Min |

| Product Size | D50: 10-850um |

| Structure | Universal Grinding |

| Transport Package | Standard Packing |

| Specification | Customized |

| Trademark | ALPA |

| Origin | Shandong |

| HS Code | 8474209000 |

| Production Capacity | 10~2000kg/H |

Packaging & Delivery

Package Size 4000.00cm * 5000.00cm * 6000.00cm Package Gross Weight 10000.000kgProduct Description

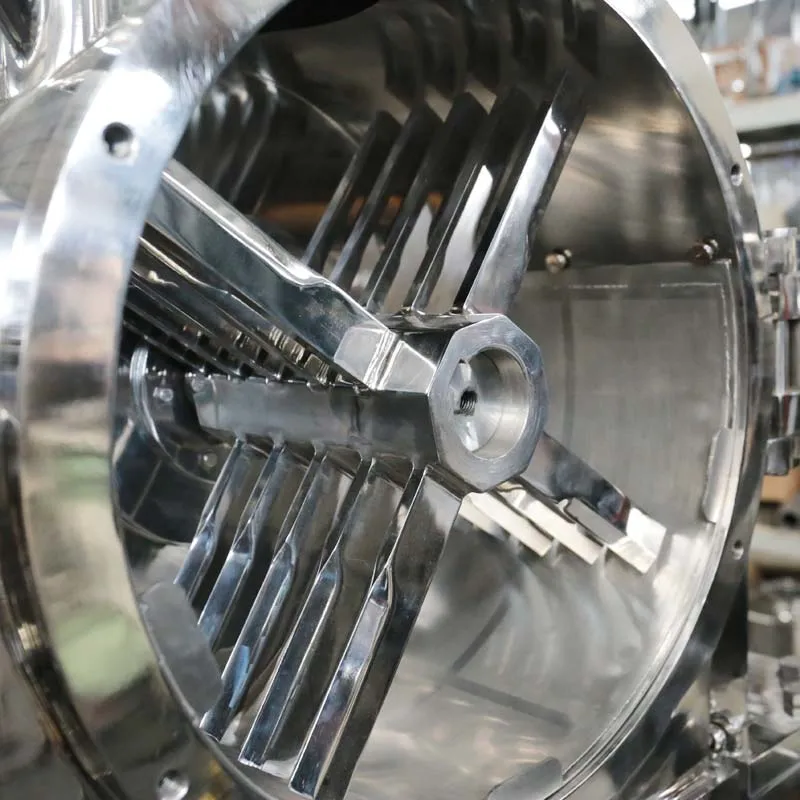

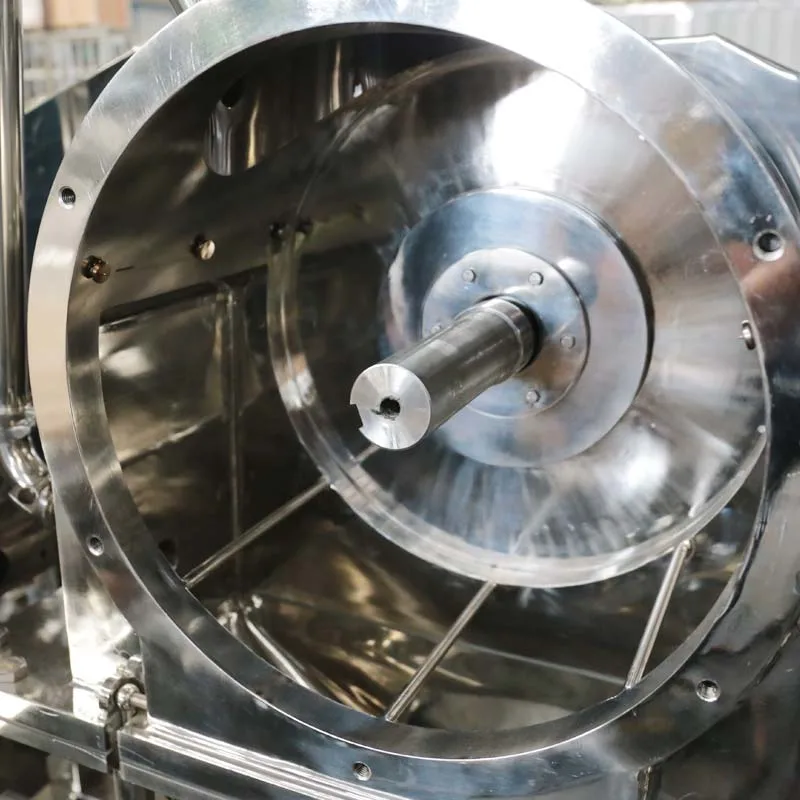

CUM-F Hammer Mill

Tooth claws, movable hammers, hammers, and grinding discs are easy to replace.It is widely used in chemical industry, inorganic salt, medicine, food, pigment, dye, pesticide, battery material, mineral, refractory material and other industries.

Working Principle & Advantages

The material is evenly sent to the grinding chamber by the feeding system, and receives the strong impact of the high-speed rotating grinding movable disk. At the same time, it receives the action of multiple comprehensive forces such as friction, shear, and collision between the static disk and the gear ring, so that the grinding, according to the nature of the material, the grinding movable disk and the static disk can be combined with different structures to meet the grinding needs of different materials.

- Particle size range D50: 10~850μm;

- The aperture of the screen is 2mm-3mm;

- Compact structure, small footprint, easy to disassemble and clean;

- The entire system is sealed and ground, with less dust, low noise, and the production process is clean and environmentally friendly;

- The control system adopts program control, which is easy to operate;

- Low installed power, wide application range and high cost performance;

- Different installation combinations are suitable for different process requirements;

- The motor can be connected with a belt to increase the speed, breaking through the problem that well-known motor brands do not have high-speed motors;

- Explosion-proof design can be selected to meet the ultra-fine grinding processing requirements of flammable, explosive and oxidizing materials;

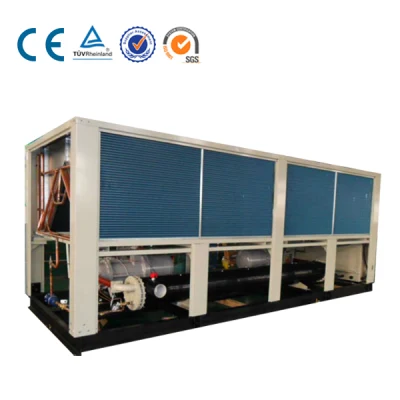

- The design of high temperature, low temperature and normal temperature can be selected, with airtight circulation and inert gas circulation to meet the requirements of crushing temperature of different materials.

Technical Parameters:

| Parameter / Model | CUM-160F | CUM-250F | CUM-360F |

|---|---|---|---|

| Diameter of grinding disc (mm) | 150 | 250 | 350 |

| Maximum speed (r/min) | 12000 | 7500 | 5550 |

| Power (kW) | 3~4 | 5.5~7.5 | 11~15 |

| Grinding fineness(mesh) | 20~325 | 20~325 | 20~325 |

| Output (kg/h) | 5~50 | 15~200 | 25~500 |

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.

Related Engineering Case:

THE WORLD'S LEADING SUPPLIER OFULTRA-FINE POWDER SOLUTIONS

ALPA is a world-renowned supplier of powder processing systems, committed to traditional powder industry development. For 20 years, focused on the research and development of dry grinding, classification, powder shaping, surface modification and provided systematic solutions. We provide customized and international certified products: Jet Mill, Air Classifying Mill, Classifier, Ball Mill and Classifying production line, powder surface modification production line, etc.

WHO CHOOSE ALPA

37 world top 500 companies, 89 Chinese top 500 companies, 169 national key laboratories and engineering technology research centers have selected ALPA. More than 3,000 customers have chosen usALPA enjoys a high reputation in more than 100 countries and regions around the world.With its high-quality products and services, it has won the trust of many well-known brand companies around the world.

Certification AuthorityALPA is one of the earliest companies in the industry that passed the ISO9001 quality management system authority certification. At the same time, ALPA has free import and export rights, and has obtained CE certification for export to the European Union and GOST certification for export to Russia. The machine design used in the medical industry fully meets the requirements of GMP certification.

Good After-sales ServiceOur after-sales service team is always ready to diagnose and solve problems for youHaving trouble with the production process? Do not worry. We will be waiting for you 24 hours a day.

About Our Equipment

ALPA can provide dry ultrafine grinding equipment suitable for various materials

Impact mill

High efficiency, has two milling effects of impact and grind, large milling ratio, simple structure, stable operation, suitable for milling medium-soft hard materials.

Jet mill

Uses the high speed turbulence airflow generated by compressed air or superheated steam as milling power. Impact extrusion, friction and shear between the particles or between the particles and the fixed plate occur, so as to achieve milling.

Ball mill + Classifying

The ball mill and classification production line refers to a complete set of milling system composed of Ball mill, cyclone, dust collector and fan.

Q: What service do you supply?A: 1). We offer consultancy for project feasibility assessment, process flow definition, preliminary layout and factory building plan, project budget, project time schedule, etc.2). We supply sample processing tests in our test station where are equipped with our various machine products, to help clients compare performances of different types of machines or process.3). We supply project engineering, automation engineering and civil engineering.4). We send engineers to the clients' project site and offer on-site technical instruction and supervision during the machine installation, commissioning and test run.

Q:How can I trust on your quality?

A: 1). All of the machine be tested successfully in Weifang workshop before shipment.2). We supply one year warranty for all equipment and lifelong after-sales service.3). We can test your material in our equipment before place the order, to ensure our equipment is suitable for your project.4). Our engineers will go to your factory to install and debug the equipment, they will not be back until these equipment can produce qualified products.

Q:Does your company provide Engineers Abroad Service?

A: Sure, we provide it. And we can provide free training for on-site workers.

Q:How to train our staff about operation and maintenance?

A: We will provide detailed technical instructive pictures to teach them for the operation and maintenance. In addition, our engineers for guide assembly will teach your staff on site.

Prev: Rotary Lobe Self Priming Sanitary Brew Beer Dairy Milk Centrifugal Pump

Next: Stainless Steel Sanitary Horizontal Rotor Lobe Pump for Viscous Liquid

Our Contact