Cost Effective High Automation Level PVC Spc Waste Material Crushing Mill Machine Spc Flooring Recycling System

Equipment parameters Products Description SPC Floor Recycle system Overview The PVC recycling system includes crushers,

Description

Basic Info.

| Knife Roll | Solid Knife Roller |

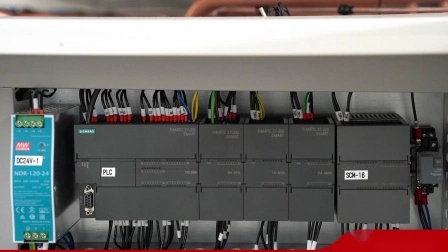

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE |

| Weight | 2t |

| Power | 165kw |

| Voltage | 380V |

| Transport Package | Small and Important Parts Packed with Plywood Case |

| Specification | 4000 KG |

| Trademark | HallMark |

| Origin | China |

| Production Capacity | 100pieces/Year |

Product Description

Equipment parametersCrusher | Model | 1000 |

| Rotary cutter diameter | 1000mm | |

| Motor power | 55kw/75kw | |

| Finished product size | 15mm | |

| Screen hole size | φ16mm | |

| Bearing brand | NSK | |

| Feed port size | 1300*550mm | |

| Capacity | 3000-5000kg/h | |

| Belt conveyor | Motor | 400W (speed adjustable) |

| Model | 850 | |

| Disc diameter | 666mm | |

| Rotating speed | 2970 rpm/min | |

| Motor power | 90KW | |

| Fan motor power | 11KW | |

| Vibrating screen diameter | 1200mm | |

| Vibrating screen motor power | 1.5kw | |

| Butterfly valve motor power | 2.2kw | |

| Finished product size | 10-30 mesh | |

| Capacity | 1500-1800kg/h | |

| Dust collector | Motor power | 5.5kw |

| Cloth bag length | 2000mm | |

| Fan air volume | 4012-7419 m/h | |

| Fan air pressure | 2014- 1320 pa | |

| General information | Voltage | 380V |

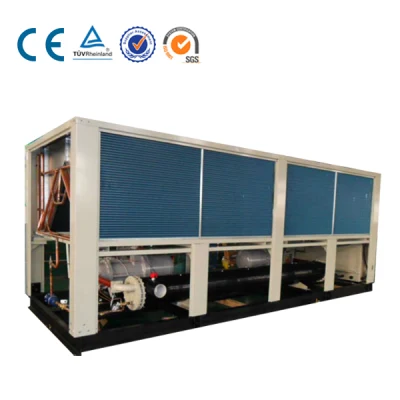

Products Description SPC Floor Recycle system Overview The PVC recycling system includes crushers, pulverizers and high-efficiency pulse dust collectors.Mainly used for recycling of PVC materials, such as LVT floors, SPC floors, plastic doors and windows,and other plastic sheet/board,with high output and stable working.The material does not to be cut,can continuously feed material at one time. The wearing part of the crusher is the cutter, which will wear out after long-term use. We use SKD-11 material, which has high wear resistance and greatly reduces the cost.

Equipment details list About us

HALLMARK INTERNATIONAL GROUP LIMITED HallMark is a professional manufacturer in flooring industry with 15 years experience,have own factory and richexperience.Products are sold to more than 50 countries around the world,such as Russia, Turkey, Egypt, Algeria, South Africa,Iran,India,Malaysia,Vietnam. The main products of our company are laminated flooring and SPC flooring production line, and othernon-standard customized equipment in the construction/wall panel/furniture industry. We can not only provide the aboveproduction lines, but also provide a complete set of solutions and technical consulting services.We provideone-stop supply and service for you ,from the raw material to machine design , production,installation, commissioning,staff training, and after-salesservice,also provide the turnkey solution. To provide customers with high-quality products,reasonable prices,timely and professional services to meet the various needs of customers. HallMark firmly believes that transaction is not the end, but the beginning of service.

Packing & Delivery

Specification

Exhibition experience

FAQ

1. Rich experience and professional designWe have 15 years experience in flooring industry,also has many years exporting experience. Each equipment location,passage will bedesigned reasonably to meet safety production.2. Competitive priceHallMark has own factory,with the same configuration,the price is competitive.And we are familiar with the Chinese market,oursuppliers provide high-quality cost-effective accessories.3. Timely after-sale serviceWe have over 15 skilled technicians offer after-sale service, will be sent to the customer's factory to assist in the installationand debugging of the flooring production line until it runs well,and asked for quick responses to customer questions within 8hours.4. One-stop solutionHallMark provide one-stop service, including market analysis and professional technical consultation,whole SPC flooring production line, raw materials ,equipment installation, personnel training,Professional after-sales service team,Renovation of old equipment,make turnkey projects.5. Quality controlStrict quality control of equipment in production and before leaving the factory, and a complete quality management system for purchased parts.Customers are always welcome to make videos or come to the factory to know the production status.6. CustomizedHallMark's engineer team will design the layout according to customer's factory space and production requirements

Prev: 5L 15L 18L 20L 30L HDPE Plastic Beer Kegs with Plastic Spear/Inner Bags

Next: 2L 3.6L 5L 10L High Quality Stainless Steel Draft Beer Mini Keg

Our Contact

Send now