Best Price Brewery Distillery Winery Cidery Milk CIP Systems/CIP System Price/CIP Cleaning System

Description

Basic Info.

| Model NO. | ACE-CIP-A21 |

| Processing Material | Natural Ingredients |

| Process | Clean in Place |

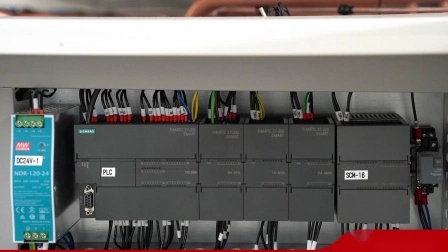

| Control System | PLC+Touch Screen Control |

| Vessels | 2 - 4 Vessels |

| Feature | Critical Cleaning, Easily Operate |

| Type | Automatic, Semi-Automatic, Manual |

| Cleaning Type | Acid Cleaning, Alkali Cleaning, Hot Water Cleaning |

| Construction Material | Stainless Steel 304/316/316L |

| Transport Package | Plywood Box for CIP System |

| Specification | 1000*650*1550mm |

| Trademark | ACE |

| Origin | China |

| HS Code | 8424899990 |

| Production Capacity | 100sets/Month |

Product Description

Custom Made Cip system, 20 Years Of Experience. Reasonable Price And Best Service, CE Certificated Products.Please Contact us for the offer.

Product Description

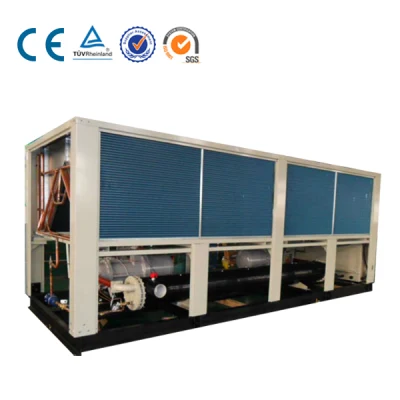

The CIP cleaning device is widely applicable to food industry,especially applicable to dairy,fruit juice and beverage etc.industries.During the food processing,cleaning and sanitation are of great importance,and measures shall be taken to prevent any pollution to food. Therefore,the CIP cleaning device is obviously indispensable.It can effectively control high organic wastes,microbes and bacteria etc. Furthermore,equipment,pipes and storage tanks that are compulsorily cleaned through CIP circul-ative cleaning fluid require no disassembly and reduce labor intensity.

CIP cart:

The portable CIP cart is composed of a caustic tank with an electric heating element, an acidic tank, a sanitary pump, a control panel and a support frame with wheels.The material of its main body is SUS304 stainless steel.The tank volume in the CIP unit depends on the brewhouse capacity and we usually offer 100 litre and 200 litre per tank for this type.

Processing order:

(1) The liquid level in tank must be adjusted before operation.(2) Cycling detergent must be released according to the switching of the flow valve. Wrong operation in the control system stops the cycling of detergent, operation will automatically stop.(3) Water temperature is adjusted by thermal regulator.(4) Air purge system starts working, most detergent can be recycled.

Advantages:

1.It can make the production plan reasonable and improve the produce ability.2.To compare with the hand-wash,it doesn't influence the cleaning result because of the worker's difference,on the contrary,it can improve the products' quality.3.It can prevent the dangers of cleaning work,so that we can save the work force.4.It can save the cleanser,the steam,the water and the cost of production.5.It can extend the service life of the machine parts.6.It includes three types,one is the handwork system,one is the semi-automation system,and the other is the whole-automation system,so it is easy for customer's selection

Industrial CIP Washing SystemsSystem IncludesIntelligent CIP system is as central integration system including WFI tank, CIP tank, plate heat exchanger, piping filter, transfer pimp, loop liquid pump, temperature controller, level controller, conduct inspection instrument, PLC touch screen, control cabinet and piping and valves etc.Work PrincipleThe cleaning liquid is automatically prepared by the CIP cleaning system through setting the program (adjustable program). The whole cleaning process including the conveying of cleaning liquids, return flow and circulation cleaning, discharging and recovery is completed through the pneumatic control valve, liquid conv

eying pump and liquid return pump. Automatic cleaning in place is realized through the control system consisting of the conductivity detector and PLC touch screen.

Tank size | 500L-10,000L | |

CIP tank type | Alcali tankacid tankhot waterclean water tankwater recycle tank | |

Cleaning recycles | Single circuitdouble circuitsthree circuitsfour circuits | |

Heating method | Coil pipes insideplate tubular | |

Automatic types and charastics | Full Automatic | 1. flow rate auto control;2. temperature auto control;3. auto compensate the cip liquid level;4. auto compensate the liquid concentrate;5. cleaning liquids auto transfer;6. auto alarm |

Semi-auto control | 1. temperature auto control2. electrical control with manual operate the other matters. | |

Manual operation | 1. manual operate on the cleaning process | |

Customer case

Certifications

Packaging & Shipping

We are experienced in the whole packing and shipping process,and we will be responsible for any damage made during shipping and send clients replacements for free.* Sufficient inner protection with different materials, including bubble bag, foam board and others.* Qualified wooden package or carton for different products or as customer require* Strict packing process to ensure the safety and completeness of the goods

FAQ

Q | Are you trade or manufacturer? | |||

A | We are a factory with an international sales company specialized in support for global distributors. | |||

Q | Can you provide instant technical consulting services? | |||

A | We are able to discuss technical details and offer suggestions over the phone in English.You can get the answers in minutes, instead of days. | |||

Q | What's the difference between Ready-To-Ship and Customized products? | |||

A | Some of RTS standard products are in stock and ready to ship in 2-3 days.We can also quick design and make the drawings for customer requirements, then begin the production. | |||

Q | What is the payment terms? | |||

A | We accept Alibaba Trade Assurance Order, also can T/T and L/C. | |||

Q | How to choose the shipment way? | |||

A | It is according to the order quantity, delivery time, costs and customs policy etc. (Or decide by customers) | |||

Q | How about the after-sales service? | |||

A | Fast after-sales support. Our products have a one-year warranty and free permanent consulting services. | |||

Our Contact