Best Commercial Kombucha Brew Tank Kombucha Tea Brewing Equipment

Description

Basic Info.

| Model NO. | kombucha |

| Power Source | Electric Steam,Gas or Direct Fire |

| Automatic Grade | Semi-Automatic |

| Brewhouse Heating | Steam Jacket , Electric Tube, Direct Fire |

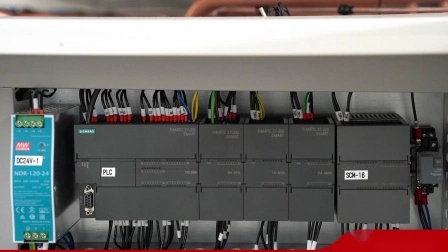

| Control Unit | Temp. Controller, HMI, PLC or Touching Screen |

| Polish Finish | 0.4-0.6 Um |

| Technology | Offer Auto CAD and 3D Design Drawing |

| After Sales Service | Installation and Equipment Commission |

| Insulation | Polyurethane Foam |

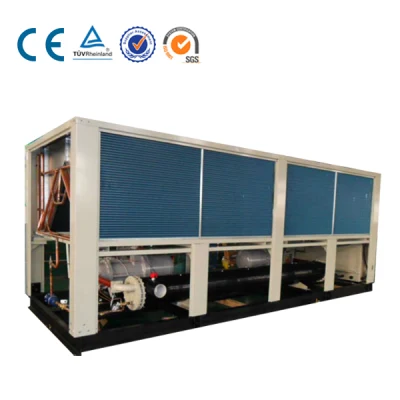

| Cooling Unit | Chiller with Glycol Tank |

| Dimension(L*W*H) | Depends on Capacity |

| Material Thickness | Inner:3.0mm, Exteior:2.0mm |

| Beer Equipment Weight | 1000kg-10000kg |

| Processing Types | Kombucha Tea Brewing |

| Voltage | 220V/380V/Adjustable |

| Main Material | SUS304 Stainless Steel |

| Transport Package | Plastic Film, Plywood Case; Container; |

| Specification | Customized |

| Trademark | METO |

| Origin | Shandong, China |

| HS Code | 84384000 |

| Production Capacity | 10 Set/Sets Per Month Stainless Steel Brewhouse |

Product Description

Best Commercial kombucha brew tank kombucha tea brewing equipment

Best Commercial kombucha brew tank kombucha brewing equipment

METO Best Commercial kombucha brew tank kombucha brewing equipment, is specially designed for the people who step into business level from Home Kombucha brew hobbies.

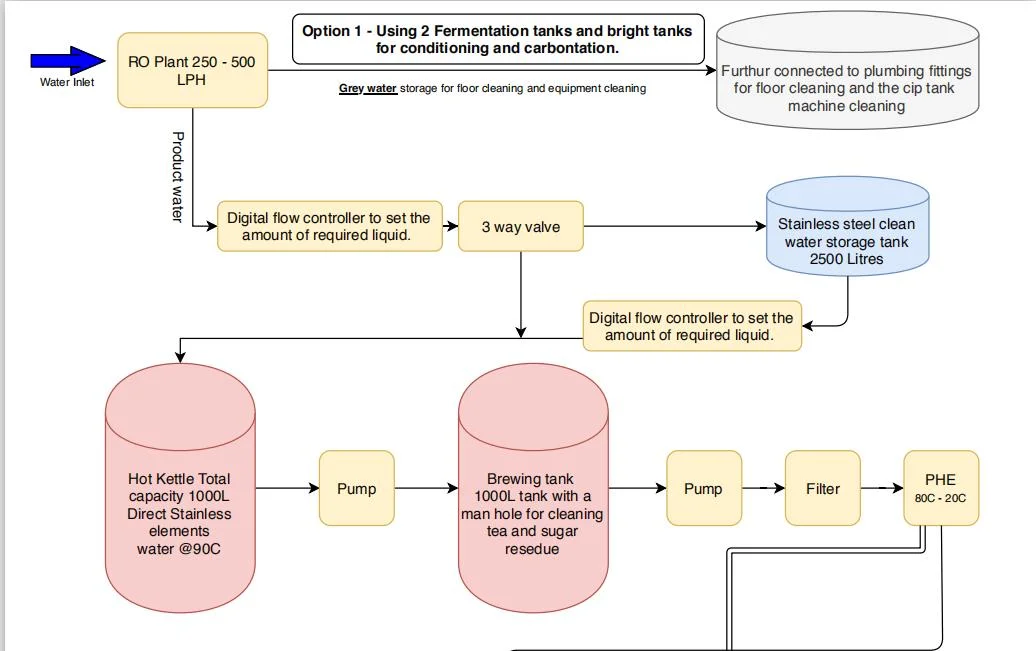

With it's customized dimension and structure, you can get very professional and cost-effective boiling and mixing of "Tea + Sugar", which will be pumped into F1 after cooling down temperature.

We can design different types of tank according to your idea, please feel free to contact us for more details!

The Best Solution for Medium-sized Kombucha Breweries

A. What is Kombucha?

Kombucha = Sugar+Tea +Scoby It is a fermented tea that has been consumed for thousands of years. Not only does it have the same health benefits as tea - it's also rich in beneficial probiotics.Kombucha also contains antioxidants, can kill harmful bacteria and may help fight several diseases. |

B. How can I choose a suitable Kombucha Brewing Equipment?

Depends on:

- Kombucha Brewing volume per day/month

- Everage local temperature

- Qualified of Water (needs to be distilled, bottle spring water, or filtered)

- Alcohol degree requirement

- Flavour type

- Flavoring Method

- Good Supplier (METO)

C. How is METO Kombucha Brewing equipment looks like and functions?

- Boil Kettle (Main part)

For 500L (other volume capacities are available) volume of Kombucha Brewing under 80c~90c degree, you need a professional tank with Agitator, which can boil the water to proper temperature and keep at that level for a period of time, and also mixing the tea and sugar well-proportioned. You can put your tea bag through the manhole (#5 in below pic).

- Whole set Brewing unit with Hot Water Tank (Water Storage Tank)

For more details, please refer to "Relative Products" or contact HULK Guys directly.

No. Description No. Description 1 Boil Kettle + Mixing Tank 6 Level Tube 2 Hot Water Tank (Water Storaging Tank) 7 Drain Pipe

3 Motor equip with Agitator inside 8 Breather Valve 4 Condensate Pipe 9 CIP Arm 5 Top Manway (Glass pressure type) 10 Platform with stairs and guardrails - Provided with installed pipes, including valves and sensors

- Integrated pump system

- CIP system: separated CIP for tanks to prevent cross product interference

- Customized PID / PLC( HMI touch screen,optional) Control System

- Staircases and platform combine vessels in a compact unit,sectional construction of the walk on surface ensures protection against slipping

Specification Descriptions Product Name 500L Commercial Kombucha Tea Brewing Equipment Kombucha Output Capacity 500L per batch, 2~4 batches per day Floor Area 3.50m(L) x 2.08m(W) x 2.7m (H) <at least 7.3m2 > Tea Types Red Tea, WuLong Tea, Green Tea, Black Tea, Loose-leaf Tea, etc. Applicable Voltage 110V/ 220V /380V/ 415V (adjustable) Power Consumming 36kw Heating Method Steam Heating/ Electric Elements Heating/ Direct Fire Heating Every METO Kombucha Brewing Equipment details is strictly in accordance with the requirements of the drawings, Customer's requirement, International QC Standards.

High standards require ourselves to complete the production process with high efficiency.

- Relative Products:

A whole set Kombucha Brewing Equipment will also need to equip with F1 and F2.

- Why and What are F1 and F2?

F1 -primary fermentation is an aerobic The SCOBY needs to "breathe" while it "eats" the sugars in the sweetened tea.

F2 -The secondary fermentation is an anaerobic process ("anaerobic" means "without oxygen"). Also named as "Flavouring Process".

You can substitute almost ANY fruit (avoid grapefruit or fruit that has anti-bacterial properties though which may interfere with the fermentation process) or fruit juice as the sugar base or fruit juice.

- Other Optional Equipments:

> Scoby Hotel

> Flavoring Tank

> CIP Chart

> OA Water Treatment Machine

> Filtration Machine

> Bottling Machine

> Kegging Machine

.....

Want to raise up more communicate about your Kombucha Project?

| 2 Vessel Brewhouse | 3 Vessel Brewhouse |

Mash/Lauter tun+Brew kettle/whirlpool tank | 1.Lauter&storage tank+brew kettle/whirlpool tank 2.Lauter&whirlpool tank ,+brew kettle 3.Lauter&HLT +brewkettle/whirlpool tank |

| Combined 3 Vessel Brewhouse | 4 Vessel Brewhouse |

| 1.Mash/lauter tun+ brew kettle +whirlpool tank 2.Mash tun+ lauter tank + brewkettle/whirlpool tank | Mash tun +lauter tank + brew kettle+whirlpool tank |

| UNit | Components | Capacity | Specification |

| Milling | Miller | 200KG/H | Double Roller,Noise<60db |

| Brewhouse | Mash/Lauter tun | 500L | Mashing Process:Decoction.Infusion.Multi-step infusion |

| Brew Kettle/Whirlpool Tank | 500L | Heating source:Steam,Electric,direct fire SUS304/Red copper | |

| Hot Water Tank | 800L | Heating source:Steam,Electric,Gas | |

| Heat exchanger | 5 SQM | Stainless steel plate | |

| Fermentation tank | Fermentation Tank (The number according to customer requirements) | 500L or 1000L | Top manway/Side manway Drying hop port to brew IPA Dimple Plate Cooling jacket Carbonation port to fill CO2 |

| Yeast Adding Tank | 5-10 L | SUS304 Stainless Steel | |

| Cooling System | Glycol Water tank | 1500L | Equiped with PU level indicator |

| Chiller | 5Hp | UL/CE certified electric elements,Copeland compressor | |

| Pump | 3T/H | ||

| Cleaning System | Disinfection Tank | 50-100L | SUS304 full welded |

| Alkali Tank | 50-100L | ||

| Pump | 3T/H | ||

| Control System | Control Cabinet | PID or PLC | |

| Optional | Auger System | ||

Packaging Details

1.LCL/FCL(20GP/40GP/40HQ).

2.Packed with plastic film in fumigation free wooden case or fixed with iron frame.

3.Up to export standard, suitable for delivery.

4.Customer's requirements available.

1. Free consultation service before, during, and after sales Layout plan in 3D or CAD drawings of your brewery;

2. Professional engineers going abroad for the installation ,debugging, and training, all the travelling cost and locate food, and hotel shall be afforded by the buyer

3. The installation period is about 15 days including assembling brewing tanks and training the operator. It is free of charge within 15 days. The buyer will be charged USD 50 per day for each engineer for the extended installation.

4. Round the clock assistance via phone, e-mail, Skype, Whatsapp, MSN, or any other communication method available to the customer.

5. Assisting purchased Facilities by seller including bottling system, steam boiler, water treatment, etc. should be installed separately. If needed, cost calculate additionally.

6. Brewing technology, brewing formula, can be offered available

7. More spare parts are available to offered freely.

Our Contact