1000L Brew Equipment for Winery

1000L Brew Equipment For Winery Jinan Chenji International Trade Co Ltd was founded in the year of 2014. Our office loca

Description

Basic Info.

| Model NO. | CJ-1000 |

| Processing Material | Stainless Steel 304 |

| Process | Mild Processing |

| Mash System | 2 Vessels |

| Fermenting Tanks | 1000L |

| Cooling Way | by The Dimple Jacket |

| Training | on-Site or Online |

| Manufacture | Yes |

| Original | China Jinan |

| Bright Beer Tanks | 1000L |

| Steam Generator | Customzied |

| Grain Miller | 100kg/H |

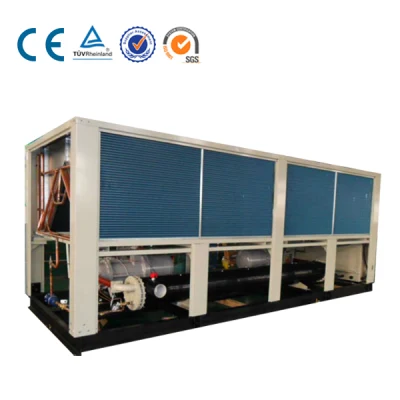

| Glycol System | Chiller+ Ice Water Tank |

| Plate Hear Exchanger | Matched |

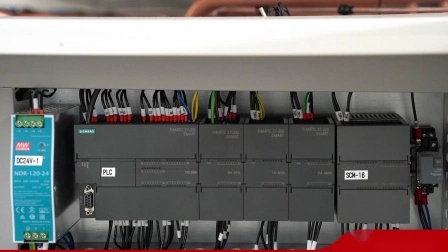

| Control | Digital Display Controller or Touch Screen |

| Solution | Turnkey Service |

| Capacity | 1000L Beer Per Day |

| Transport Package | Container Loading Plywood Case |

| Specification | 1000L |

| Trademark | CJ or EOM |

| Origin | China Jinan or Others |

| HS Code | 8438400000 |

| Production Capacity | 300set Per Year |

Product Description

1000L Brew Equipment For Winery

| Equipment Request | Components |

| 1. Milling System | Malt Miller |

| 2. Mashing System | Mash/Lauter Tun |

| Boiler Tank | |

| Boiler | |

| Heat Exchanger | |

| Wort Pump | |

| Stiring Device (Optional) | |

| Other accessories are available: 1. Ornamental Pipe; 2. Mashing Pipeline; 3. Operating Plateform; 4. Yeast Feeder; 5. Venturi Tube; 6. Butterfly Valve DN40; 7. Butterfly Valve DN32; 8. Soft Pipe; 9. Dregs Rake; 10. Sugar Measuring Cylinder; 11. Saccharimeter; | |

| 3. Fermenting System | Fermentation Tank |

| Other accessories are available: 1. L-Pipe; 2. Butterfly Valve; 3. Pressure Gage; 4. Solenoid Valve; 5. Vacuum Valve; 6. Cooling Pipe; 7. Thermal Insulation Pipe; | |

| 4. Cooling System | Ice Water Tank |

| Refrigeration Machine | |

| Centrifugal Pump | |

| Evaporator | |

| Ice Water Pump | |

| Relative Pipes and Valves | |

| 5. CIP System | Washing Tank |

| Sterilization Tank | |

| Pump and Valve | |

| 6. Filter System | Kieselguhr Filter |

| Membrane Filter | |

| Filtered Beer Tanks | |

| 7. Packing System | Fresh Keg Packing Machine |

| Pop Can Packing Machine | |

| Glass Bottle Packing Machine | |

| 8. Controlling System | Mashing Control Panel |

| Fermenting Control Panel | |

| Refrigerating Control Panel |

Jinan Chenji International Trade Co Ltd was founded in the year of 2014. Our office located in Jinan City that is famous of the Spring Water all over the whole country. Client can arrive to visit us by the Jinan YaoQiang International Air Station.

Our mainly business: Beer Brewing Equipment 1bbL 2BBL 3BBL 5BBL 7bbl 10BBL 15BBL , OEM customized cone fermentation tanks, Jacketed or without Jacket from 50L, 100L, 500L, 1000L, 2000L, until 4000L which are all suitable for the ocean container loading from China to Buyer, the main market is: USA, Canada, Mexico, Argentina, Australia, UK, Germany, Spain, Italy, Brazil, New Zealand, Singapore, Thailand, etc..

Its widely used for the small or large brewery 1000L-4000L Beer Per Day, Commercial pubs, brewpub 200L-500L per working Day, School Teaching and Researching, and Hotels, restaurant etc. Our service is the one stop turnkey project: Malt Grain Grinder, Kettle, Hot water tanks, Fermentation Tanks, Controller, Cooling System (Refrigerator and Ice water tanks) , Yeast tanks, or the beer selling: beer kegs filler/washer, bottling machine, canning machine etc.

We accept the personal customization according to buyer real site, you can name your logo on the tanks, also we arrange the container loading once the brewing project finished well, and delivery to your port , even door to door service.

We have our own technical and research team. Before the package we will sign all pipes and supply the installation pictures, or On-site installation training by our worker to your brewery city.

Inquiry with us, let's start the talking ASAP.

Application

Our beer brewing equipment is widely used for the small or large brewery 1000L-4000L Beer Per Day, Commercial pubs, brewpub 200L-500L per working Day, School Teaching and Researching, and Hotels, restaurant etc.

Our Service

Customized according to your personal request based on our standard configuration.

After Sale Service for whole life if you have request.

24 hours on line, supply solutions any time

3 Years Warranty for the Main Equipment.

Spares parts replacement and repair service

Engineer goes to your city for installation, debugging and brewing training if you need

Provide the import documents that you need for customs clearance and reduce Tax.

Supply the latest news for the brewing industry and brewing technology

Port to Port, Door to Door service

One Stop Turnkey Project service

FAQ

1

Q: Are you professional Supplier and tanks Manufacture ?

A: We are the manufacturer of beer brewing equipment for 15 Year and deal in export business since 10 years ago .

2

Q:Can I have the customized products with personal design?

A:Yes,we support any of your wish design,can design and manufacture as client's requirements.

3

Q: Can you guarantee your beer brewing system quality?

A: All of the equipment will be inspected before the package, appliance of the international Standard.

4

Q:How about the after sales service?

A:For our after-sale service, we promise all life of technical support to all client.

All of our products is available with 10 years warranty even for spare parts within quality warranty period, our service is free of charge.

5

Q: Which export port you use?

A:Commonly we will use Qingdao port, sometime, can be other port as your wish.

6

Q: I am green hand in brewery industry? Could you supply training for us?

A: Yes, our engineer can supply the installation equipment and brewery training service overseas.

7

Q: What is your payment item ?

A: We accept 40%TT + 60%TT as for the balance payment before the delivery.

Prev: 1000L Micro Beer Plant Winery Equipment Beer Brewery Turnkey Brewery Systembrewing Beer Equipment

Our Contact

Send now